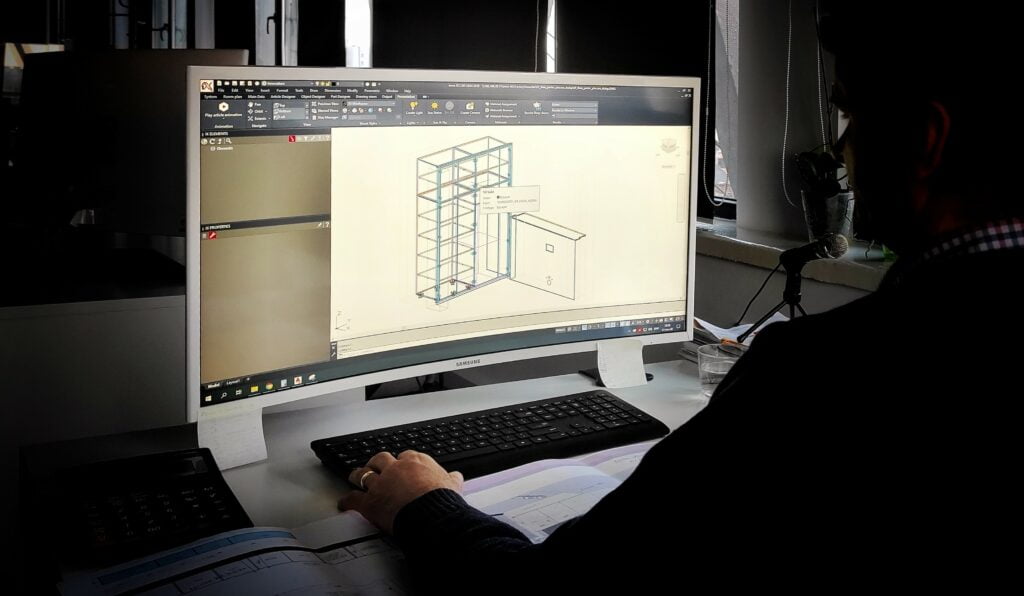

The evolution of technology has brought changes in all areas, including the furniture industry, where it has eliminated much manual labour. Hand-drawn technical drawings have been successfully replaced by the ones created on the computer. Thus, a design software has become a necessity for the custom furniture manufacturer.

Computer-aided design creates computer models defined by geometric parameters. These models can be viewed as 2D or 3D representations and can be easily modified by changing the relevant parameters.

I have listed below some of the advantages you can gain by using CAD software in furniture design.

Increase designer productivity

CAD software allows designers to work faster and smarter, lowering design costs and completing projects faster. This allows you to sell quality products at lower prices, increasing your competitiveness in the market. CAD design execution has been shown to be 3 to 10 times faster than paper design.

Improve design quality

The use of CAD software allows the design team to control the quality of the designed product. It's easy to spot errors, identify problems and fix them before the project is sent to production. 3D design helps the designer to create a virtual space identical to the one in which the finished project will be placed. This gives a clear view of the spatial fit and functionality of the designed furniture.

Modify projects extremely easily

If you have to make one-off changes to what you've already designed, it's very easy to do them. You can keep several versions of the same project and return to any of them at any time.

Get the lists of needed materials and accessories

Once you have completed the design, you can generate lists containing the materials and accessories required for the project. This makes it much easier to place accurate and complete orders to suppliers.

Improve communication between departments using production documentation

The documentation of CAD projects is complete and easy to read by the production department. The working drawings are to scale and very accurate. This eliminates errors that could be created by misinterpretation of drawings or incomplete execution dimensions.

Create a database for production

A furniture database that is production-ready is ideal for any furniture manufacturer. All CAD-designed furniture is saved and can be modified or reused for future projects. It's true that this process takes a lot of time but, once built, it will bring you significant cost savings,

Create 3D models

If you've ever tried to create a 3D model by hand, you surely know how difficult and time-consuming it is. CAD software can turn your 2D project into a 3D one in seconds. From here you can export photorealistic 3D images from various perspectives, to show to your customers, to have a clear picture of the furniture they have ordered.

In addition to all these advantages, CAD software has the disadvantage that you need experienced designers in its use or you have to be prepared to spend time and money to train someone for this. There are, however, faster and more efficient solutions to this shortcoming: standard or customized furniture databases. You can find out more about this here.

CAD files can be integrated with CAM (Computer Aided Manufacturing) software for full automation of furniture manufacturing, but we'll talk about that in a future article.