The configurator contains multiple options for important variables in setting the furniture. For example, according to the type of the selected cabinet, the system displays fields and subfields that allow you to make the desired settings such as:

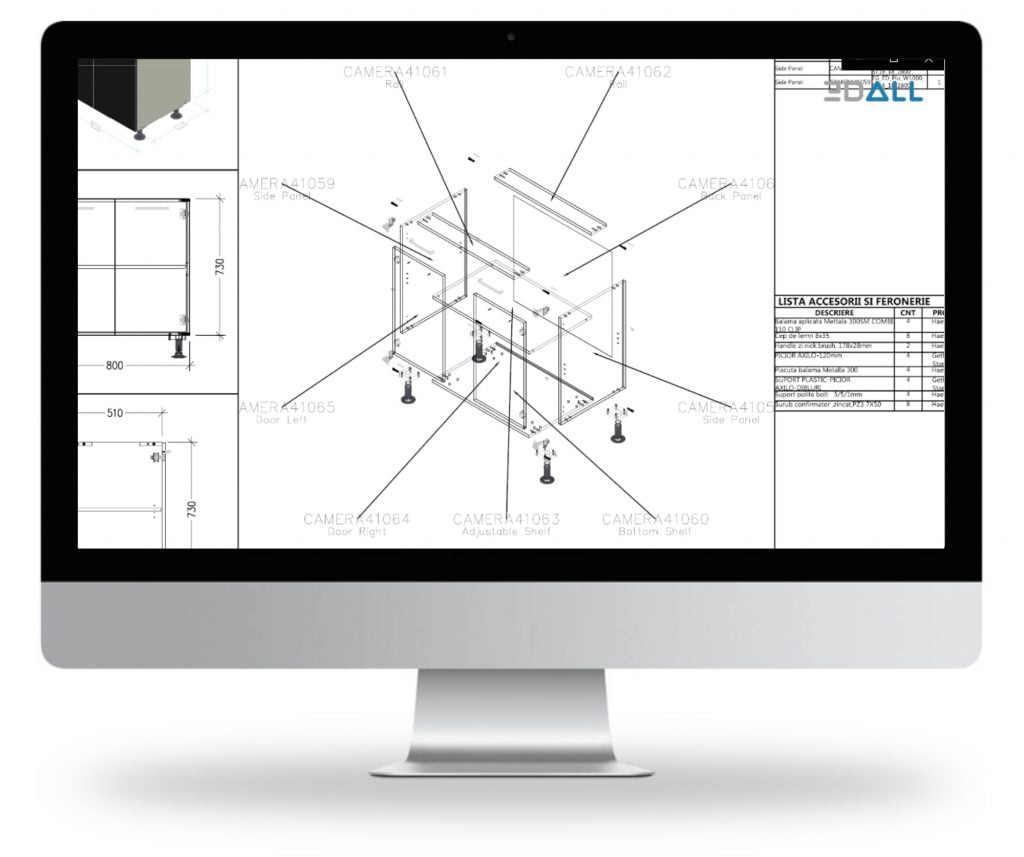

Constructive principles: case size, connection type, number of shelves, foot height, lower and rear panels constructive way, channel's depth for the HDF panel, rails' width, shelf withdrawal and terminal side panels options

Front panel: constructive mode of the front panel, door opening direction, door type, material type, chipboard thickness, decor and supplier, edge thickness and decor

Case materials: chipboard thickness, supplier, decor, edge dimension and decor, panels with different decors, decors for the back panel

Accessories: Euro screw, wooden plug, number of holes for the shelf pins, hinges supplier, legs type, hanging elements

Drawers: drawer type, box material, box height, the type of connection for the box, type of the slide and the supplier etc.