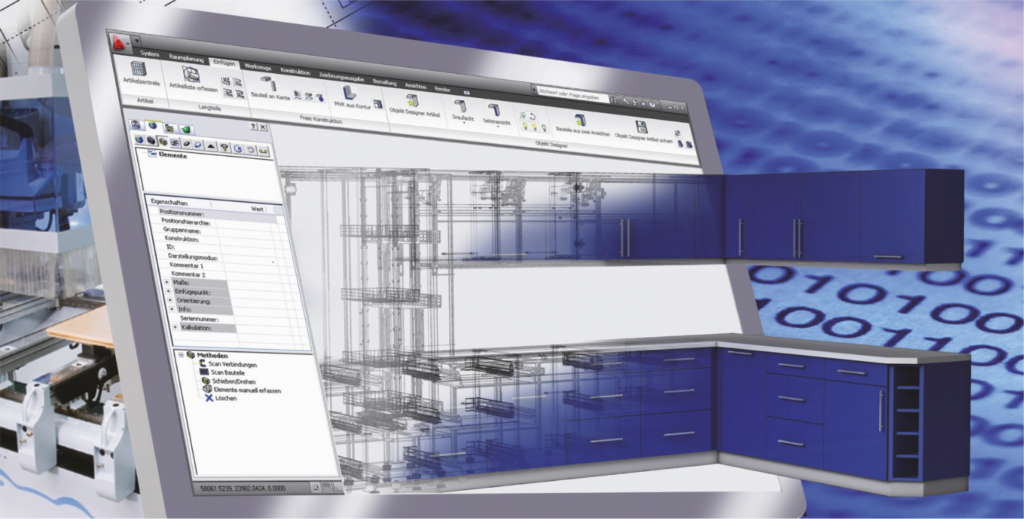

If in the previous article we discussed the benefits of computer-aided designin today's article we will talk about CAM (computer-aided manufacturing) systems. These are used in furniture production processes for complete factory automation.

Traditional manufacturing methods rely on engineers to program the machines used in the manufacturing process. The CAM system replaces hand-made drawings with software that defines the actions and processes of a machine. This allows designers to send drawings and specifications directly to machines. This means that CAD design documentation is automatically integrated with CNC machines and manual set-up is no longer necessary.

The main goal of computer-aided manufacturing is to create a faster production process while reducing material and energy consumption.

Here are some of the benefits you can get from using a CAM software in furniture production:

Higher speed in the production of furniture components and increased precision

Computer-aided manufacturing can significantly speed up the production process without compromising on quality or accuracy.

Machines can be programmed to create the same product once or several times with maximum precision. If you want to make more than one panel of the same type, a CAM system ensures that each component is exactly the same.

Increased production efficiency

Computer-controlled machines don't need breaks. The machine can have a constant engagement, which will lead to no downtime in production.

Reduced labour costs

By automating most of the manufacturing process, labour costs can be reduced. You will still need skilled people to operate, maintain and repair machinery, but the number of employees will be much lower than without CAM.

Simplified communication

CAM software translates drawings and data into detailed instructions that operate automated machines and also eliminates human error.

Saved design data

One of the biggest benefits of CAM software is the ability to save the information you enter into the system. This makes future projects much easier to program.

A manufacturing database

The database created through CAD/CAM integration includes all product data generated during design (shape and dimensions, bill of materials and their specifications, parts lists, etc.).

Resources optimisation

Using CAM helps avoid most production errors. This reduces the amount of waste that normally results from manual processing. By making more products from the same amount of raw material, you can increase your profit, set competitive prices, or do both.

Increased control over production

Introducing CAM into a furniture factory increases the degree of control you have over the whole process. Through a function called a CAM tree, you can follow a manufacturing process from start to finish. This gives you control over stock, machinery, materials, post-processing and many other features.

Although the use of CAM in furniture production offers many benefits, it also brings with it some challenges, such as:

High cost of installation and maintenance

Initial costs (hardware and software investment) are high, with the investment in these systems being amortized, in some cases, in a few years.

The need for skilled labour

To operate CAM tools you need skilled CNC machine operators with a good understanding of these systems. They should also be trained on how to troubleshoot the tools. This training may require constant updates as systems gain new features and capabilities.

However, the balance of advantages/disadvantages is definitely in favour of using digital solutions for production automation in furniture manufacturing.